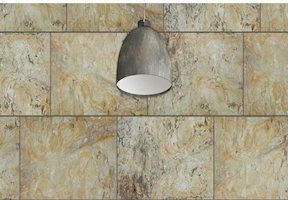

When looking for a stone to use indoors, outdoors, in a commercial area, or for a home project, porcelain is the one material that fits every demand. Porcelain is a term that has been tremendously popular in the stone market. The major reason behind its popularity is the range of advantages it offers for distinctive project requirements.

It is a hard stone that offers toughness and adaptability, along with some great looks. Isn’t it great how one stone can consist of a lot of different features? But have you wondered how this stone gets all these features and what the porcelain manufacturing process includes?

Let’s go over the fundamentals of the porcelain slab-making process:

What are porcelain slabs?

Porcelain slabs are engineered stone slabs made by firing dense clay at a very high temperature. The process of baking at high temperatures makes these slabs hard and dense, with a water absorption rate of less than 0.5%.

These slabs are designed specifically to mimic the look of natural stone tile flooring while adding the functionalities of engineered slabs. This combination creates a highly durable and beautiful stone slab that works well for a range of different project requirements.

How are porcelain slabs made?

Creating porcelain slabs goes through a series of steps, which are as follows:

1. Raw Materials and Preparation:

The precise selection of raw materials is the most critical component in the manufacturing of porcelain tiles since it determines the body component. To produce the required color and hardness attributes, the proper amount must be mixed.

Making porcelain slabs begins with carefully selecting the proper amount of raw materials, which generally include clay, silica, feldspar, and other minerals. All of these elements are then carefully combined to create a homogeneous combination that ensures the product’s quality and consistency.

After that, water is slowly added to the mixture to create a paste-like substance known as “slip“.

2. Shaping the Slabs:

The next step in the creation process includes the addition of ceramic pigments to the slip, which includes color ingredients to achieve the desired color for the slab. This slip is then poured into molds to shape the porcelain slabs.

There is no such thing as a diameter consideration for molds; they can be of various sizes and designs that allow room for customization. Then, the excess water remaining in the slip is gradually removed through a process known as “dewatering,” which gradually allows the material base to solidify within the mold.

How To Cut Porcelain Slabs: A Comprehensive Guide

3. Pressing or extrusion:

The next process followed is the pressing of slip, which involves hydraulic presses that help shape the slabs. In this process, the slip is placed between two large molds, and then immense pressure is applied to it to compact the material.

This method of shaping is also known as dry pressing. Then the process of extrusion starts when the remaining slip is pumped into an atomizer, which consists of nozzles to create slabs.

4. Drying:

When the shaping is done, the slabs are required to dry thoroughly to remove any remaining moisture in the mixture. Drying plays a vital role in the making of slabs, and it should be done properly to make the slab durable and free from cracks and deformities during firing.

The drying process can take as much time as possible; it can take from several hours to a few days, which highly depends on the thickness and size of the porcelain slabs.

5. Firing:

After drying up, the porcelain slabs are then fired in kilns at extremely high temperatures, which is the main reason for their hard surface. The kiln temperature generally ranges from 1200 to 1400 degrees Celsius (2192 to 2552 degrees Fahrenheit).

Due to this firing process, the raw material then transforms into a solid and dense porcelain slab. The high temperature also gives the porcelain its remarkable strength and durability.

6. Glazing (optional):

For some specified glazed porcelain tiles, a layer of glaze is applied before the second firing. Glazing the tile usually enhances the overall aesthetic appeal of the surface and provides additional protection.

This process can also help add different textures or finishes to the surface. Glaze is a liquid-like texture that, when fired at a high temperature, forms a glass-like layer on the surface of the porcelain slab.

7. Second Firing (if glazed):

A second firing of the slab is only required when the glaze is applied to the surface. It is usually done at a slightly lower temperature than the first firing. The following firing helps the glaze fuse on the surface.

This process is essential if there is a requirement to create a smooth, glossy, or textured finish, depending on the desired outcome.

Vitrified Tiles vs. Porcelain Tiles

8. Quality Control:

Quality control is an essential step, as it ensures the outcome of the process and whether it meets the requirements. In this process, the porcelain slabs undergo rigorous quality control checks.

In this, we look into whether slabs meet the required standards for size, color, shape, strength, and texture. And if we see any defects or imperfections, we eliminate them at this stage.

9. Cutting and Finishing:

After passing the quality controls, slabs are then cut into the desired sizes with the help of specialized machinery such as diamond-tipped saws. Then the finishing of the edges is provided using various techniques to achieve the required look, such as beveled, rounded, or straight edges.

10. Packing and Distribution:

And then our process ends with carefully packing the porcelain slabs to prevent any transportation damage. Slabs are then transported carefully and distributed to distributors, retailers, or directly to project sites, where they will be used to create stunning surfaces in homes and commercial spaces.

Conclusion:

The process of manufacturing porcelain slabs is a demanding and intricate one that mixes traditional craftsmanship with cutting-edge technology. Each stage in the production of these exquisite and durable surfaces that have grabbed the hearts of designers, architects, and homeowners alike is critical, from raw materials to final goods.

Understanding the manufacturing process for porcelain slabs increases our appreciation for the beauty and inventiveness that go into creating these magnificent works of purely functional art.